Classification

Contact Us

501, 502 and 601, Building 4, Phase 2, Beijiao Kai Tak Real Estate Park, Shunde District, Foshan City, Guangdong Province

Modified polyester resin

Keywords: water-based epoxy resin/water-based acrylic resin/water-based polyester resin.

Product Classification:

Product Details

Product introduction:

★This product is a modified water-based polyester resin designed for water-based baking varnish. And water-based amino resin used in conjunction.

★Good adhesion to all kinds of metal substrates. Excellent adhesion on aluminum, aluminum alloy and galvanized sheet.

★And amino crosslinking, this product has excellent rust resistance and hardness and flexibility of the balance, as well as a variety of chemical resistance.

Part II: Product Technical Indicators

| Serial Number | Name |

| Name | WX-194 waterborne polyester resin (dispersion) |

| Appearance | Translucent blue light dispersion |

| Solid | 40±2% |

| hydroxyl value | 120±5 (at 100%) |

| PH value | 6.5-7.5 |

Part III: Instructions for Use

★Adjusting the pH when using this product will significantly affect its viscosity. The pH value is high, the viscosity will be significantly larger, and vice versa.

White paint ratio example: (Water-based industrial baking varnish)

| Serial Number | % W | |

| WX-194 | 46.3 | |

| Cymel303 | 4.6 | |

| TGEO-270 | 2 | |

| dimethylethanolamine | 0.9 | |

| 70% titanium dioxide water slurry | 40.8 | |

| 107L | 0.2 | |

| deionized water | 15.4 | P/B=1.1 |

| Total | 100 | NV=52% |

★Basic performance indicators (150 ℃ (plate temperature) baking for 30 minutes. Plate: polished tinplate)

| Pencil hardness | Gloss (60 degree angle) | Acid and alkali resistance (0.1mol sulfuric acid, sodium hydroxide) | Adhesion (100 grid) | MEK-resistant, 100 times | Salt spray (grinding cold rolled steel plate) |

| ≥ 3H | ≥ 90 | Acid: 120h; Alkali: 240h | Level 0 | Slight loss (not soft) | 240h(25 film thickness) |

PART IV: PACKAGING AND STORAGE

Effective storage period from the date of packaging: 6 months

200KG/barrel

Part 5: Relevant Performance Test Reference

| Project | Picture | Phenomenon |

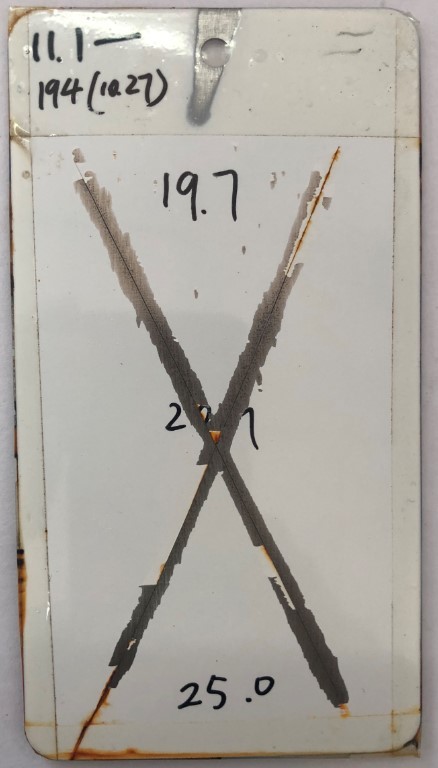

| Salt spray test |  |

L test based on national standard GB/T 1771-2007 L 5% salt spray time is 48 hours, and the fork place blisters and falls off 4mm. l Film thickness 20μm ~ 25μm |

| Project | Before wiping | After wiping | Phenomenon |

|

Resistance to solvent wipe test |

|

|

l Test based on GB/T1726-79 l solvent for wiping: butanone l Number of wipes:100Times No change in gloss and hardness before and after wiping |

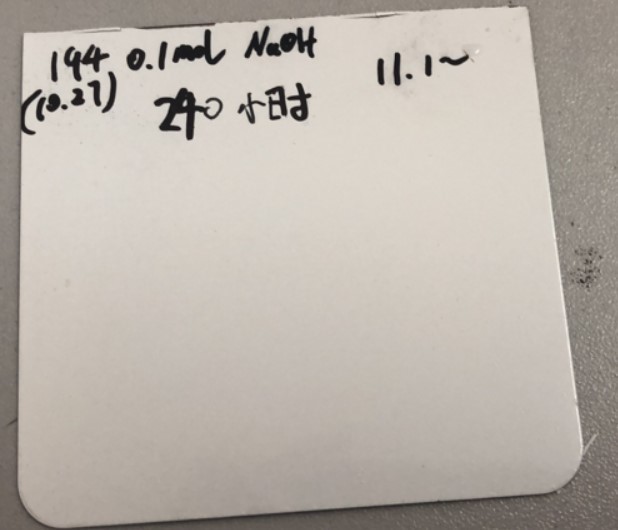

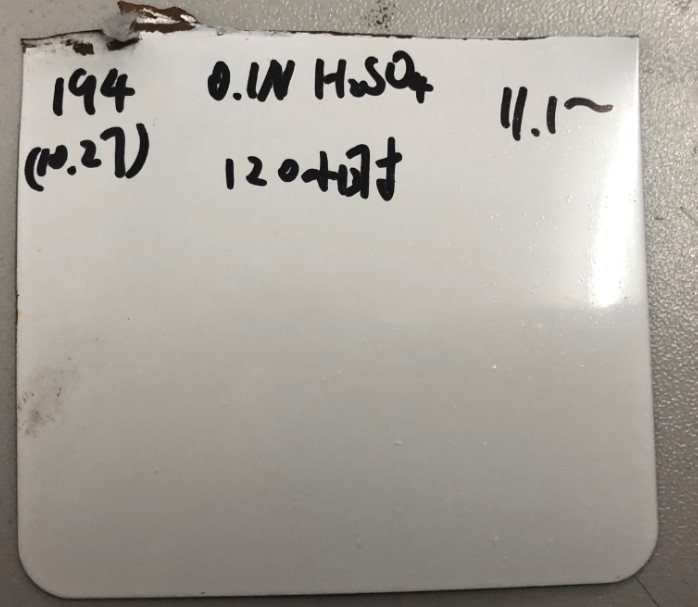

| Project | 0.1N NaOH | 0.1N H2SO4 | Phenomenon |

| Acid and alkali immersion test |  |

|

Slight blistering appears on the surface after alkali-resistant soaking for 240 hours; slight blistering appears on the surface after acid-resistant soaking for 120 hours |

Related Products

Product Message

Focus on us

WEB

24-hour customer service hotline

Address: 501, 502 and 601, Building 4, Phase 2, Beijiao Qide Real Estate Park, Shunde District, Foshan City, Guangdong Province

Telephone:+86-757-23622292

Mobile:+86-13827784647

E-mail:wanxia_sd@163.com