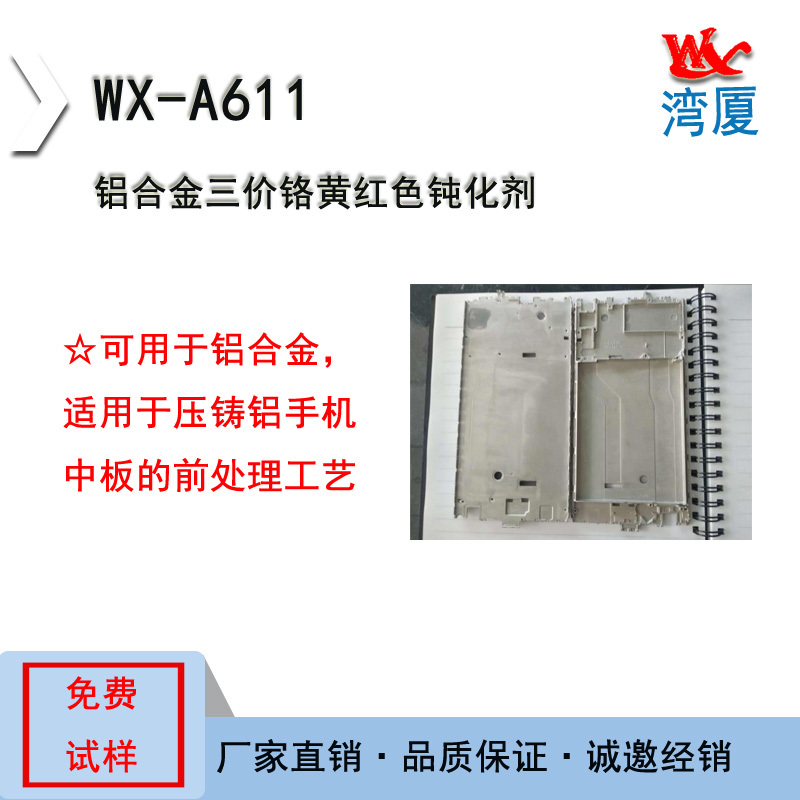

Trivalent chromium yellow-red passivator for aluminum alloy

Keywords: water-based epoxy resin/water-based acrylic resin/water-based polyester resin.

Product Classification:

Product Details

Product Introduction

A611 aluminum alloy trivalent chromium yellow red passivator is a kind of film appearance of yellow red passivator, mainly used in aluminum alloy mobile phone plate, especially in 5G mobile phone plate, neutral salt spray resistance can reach 24-96 hours (depending on the material). Has the following characteristics:

- Stable operation, good passivation effect, excellent corrosion resistance, long resistance to neutral salt spray.

- It can be used for aluminum alloy, especially suitable for the pretreatment process of die-cast aluminum mobile phone plate.

- A layer of yellow-red film is formed. The film has a low contact resistance of less than 0.8 mOhm/cm2, high temperature resistance and so on.

- Environmental protection, safe and non-toxic, in line with EU RoHS regulations. Wastewater treatment is simple.

- Suitable for dipping, spraying, manual wiping.

Grooving and Groove Control

After the working tank is cleaned, the tank shall be slotted according to the proportion in the following table, and the parameters of the tank shall be controlled according to the data specified in the table:

| slotting ratio | 10%-20% | |

| Tank control | trivalent chromium ion concentration | 0.12-0.2g/L(10% open) |

| PH | 3.8-4.2 | |

| Working temperature | 25-40 ℃ | |

| Processing temperature | 60-80 seconds (depending on the specific working conditions) | |

Remarks:

- When slotting, the stock solution and water should be mixed evenly, and then the pH of the working solution should be measured. If the pH is not within the required 3.8-4.2 range, adjust it to this range.

- The operation should wear protective gloves, open the lid after not used up the product liquid should be sealed in time, properly kept.

- If the pH is high, adjust slowly with 5% sulfuric acid solution; if the pH value is low, adjust slowly with 1% sodium hydroxide.

Determination of pH value: take 1000ml of bath solution, measure with pH meter, and read the stable value as the pH value of working solution.

determination of trivalent chromium ion concentration:

- Accurately remove 25mL of the solution to be tested into a 250mL conical flask. 50mL of pure water, 10ml of 50% sulfuric acid solution, 1ml of concentrated phosphoric acid, 10ml of 1% silver nitrate solution and 2g of ammonium persulfate were added in turn and shaken well.

- Place on an electric furnace, heat and boil for about 2min, cool to room temperature, add 5-6 drops of vanadium reagent (phenyl anthranilic acid) indicator, shake well.

- Titrate with 0.1mol/L ammonium ferrous sulfate standard solution until the color changes from purple to yellow-green. At this time, the volume number of 0.1mol/L ammonium ferrous sulfate standard solution consumed is V, unit mL, and the calculation formula is as follows: trivalent chromium content =(0.1 ×V) × 52/3/25g/L

Tank maintenance

- The actual production consumption is mostly carried out consumption, and the pH value of the bath solution and the concentration of trivalent chromium ions should be regularly detected during the production process.

- There will be a small amount of precipitation in the tank liquid after long-term use. It is recommended to use the environmental passivation tank with a filter.

- About 80 ml of trivalent chromium passivator is added to each 2.4m ² product processed in the 200L tank, and the specific data are determined according to the actual working conditions.

- 200L tank, continuous production, and normal supplement of liquid medicine, treatment area reached 1000-1600m, please replace the tank liquid (this data is for reference only, the actual production of products on site depends on the material).

Equipment Requirements

The tank body should be lined with PP/PVC material, with constant temperature device, preferably with mixing device.

Precautions

- If used for the first time, the tank must be thoroughly cleaned.

- When too much precipitation in the working tank affects the passivation effect of the workpiece, or the treatment effect is not significantly improved by adding the stock solution, the tank liquid should be replaced and the tank should be re-slotted.

- Appropriate stirring during work is beneficial to the improvement of passivation effect, and frequent impact of the workpiece should be avoided during passivation and after passivation.

Transportation and storage

- The product should be handled gently, and it is strictly prohibited to use dangerous actions such as falling, throwing and bumping;

- The storage place should be ventilated, dry and cool, and it is strictly forbidden to be exposed to direct sunlight or outdoor;

- Do not be close to heat source, acid and alkali, oxide and other corrosive substances;

- Do not place upside down or open.

Waste water treatment

Discharge after treatment according to local regulations.

Safety Instructions

Use as much as possible to avoid eye contact, can not be swallowed, use should have good ventilation equipment, and the use of personnel operation should be with rubber gloves, such as accidentally touch the eyes or skin, with a lot of water can be washed. Please send for medical treatment if necessary.

Related Products

Product Message